The movement of the engineers gravitates toward the aircraft, a white, twin-engine, 19-seater commuter airplane code-named N-219. “N” stands for Nusantara (Archipelago).

Twenty-one years after the historic first flight of the N-250 on Aug. 10, 1995, Indonesia finally has another homegrown airplane, designed and built by the nation’s own people.

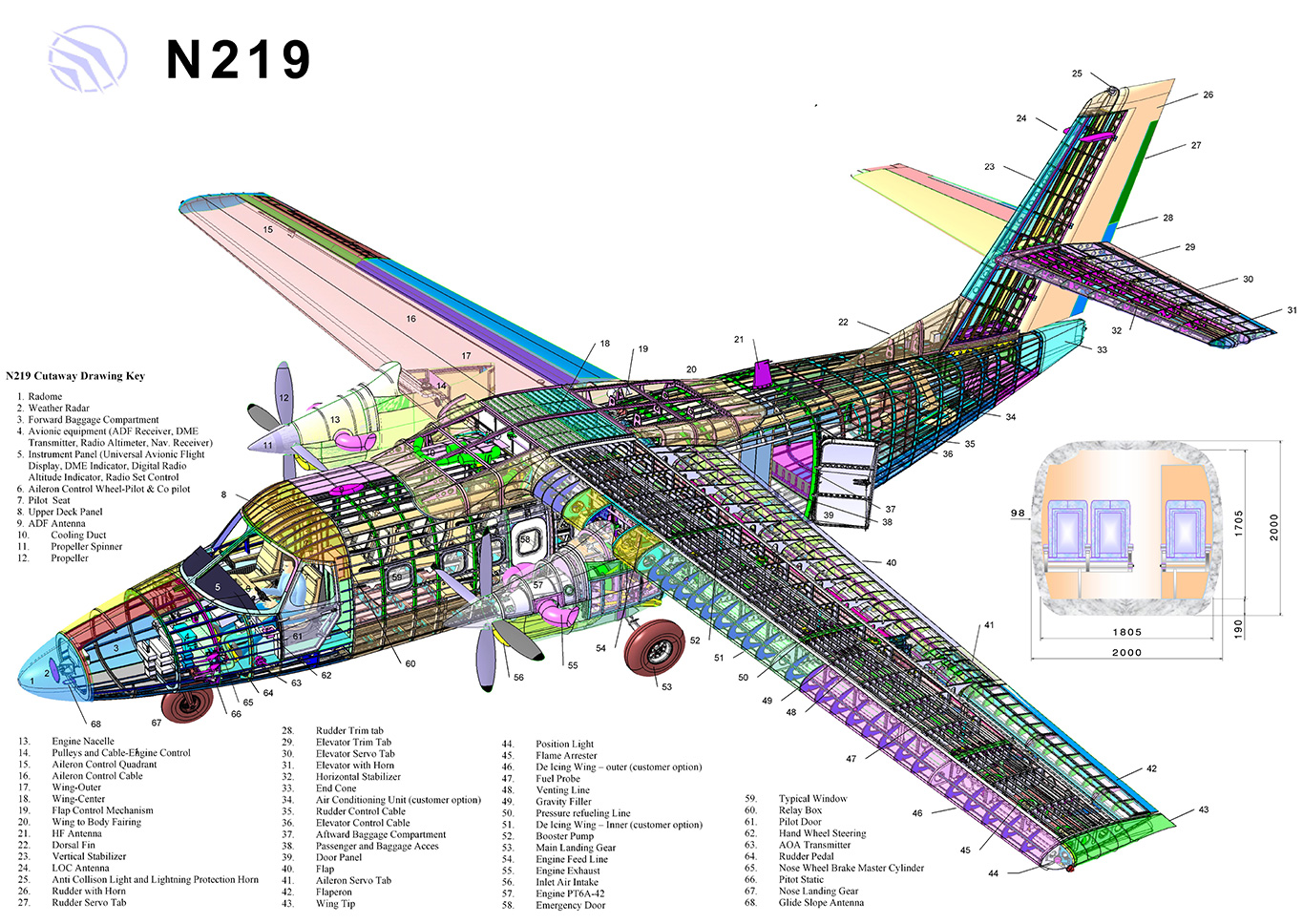

Budi Sampurno, the project manager for the N-219, walked The Jakarta Post team members across the white, painted floor in the hangar of state-owned aerospace company DI in Bandung, West Java. As they approached the plane from the front, all eyes were captivated by the object of pride for Indonesia’s aerospace industry, measuring 20 meters in wingspan.

Budi looked at the aircraft as if it was his own child. The N-219 stood in a blue steel construction called an aircraft jig, where workers attach components to a plane. “We use local vendors to supply 80 percent of the jig and other manufacturing tools,” Budi, who is in his late 60s, said proudly. “The N-219 is a national program, so we want to involve local industries as much as we can.”

While its predecessor, N-250, was a state-of-the-art aircraft at the time, the N-219 was designed to fit its purpose: to serve remote areas and connect the vast archipelago, as mandated by Indonesia’s founding fathers. Although the company has recorded many achievements, N-219 is considered DI’s first giant leap since the development of the N-250 by PT Industri Pesawat Terbang Nusantara (IPTN), DI’s former name.

“The N-219 is a breakthrough that will help DI rise again,” Budi said.

Graduated from Gadjah Mada University (UGM) and the Bandung Institute of Technology (ITB) and specializing in structure design engineering, Budi has led a team of 350 engineers to develop the N-219 since 2011. Although most of the team members are men, 20 percent are women.

DI also brought back at least 25 retired engineers, who in the process of developing the aircraft are accompanied by three to four young engineers. This way, the youngsters are expected to foster their skills and accumulate experience before they take over the development of the aerospace industry.

The team is divided into specific tasks: structure and system analysis, design department, flight physic analysis and flight test analysis. Most of the team, up to 200 of 350 engineers, are involved in the structure and system analysis and design department.

The project, which used less than US$100 million, is sponsored by the State-Owned Enterprises Ministry, the Research, Technology and Higher Education Ministry as well as the National Institute of Aeronautics and Space (LAPAN).

Moving forward despite tough times

The plan to commercially produce the N-250 was canceled due to the Asian economic crisis in 1997. Inspired by the vision of former vice president and third president Bacharuddin Jusuf Habibie, IPTN’s N-250 aimed to connect all cities and remote areas in Indonesia.

Under the fourth president, Abdurrahman Wahid, IPTN was reborn into Dirgantara Indonesia in 2000. Instead of striving to develop another N-250, DI decided to become a business-oriented company. It went through a long restructuring phase, which included the massive layoffs.

In desperate times, in early 2000, DI had to accept an order to produce cooking pan molds. Some of the employees still look back at that time with bitterness. In 2007, a court declared DI bankrupt.

However, the company continued to receive orders from global aerospace companies. Some of the achievements included forming joint ventures with British Aerospace to produce Airbus A380 wing parts, with Eurocopter (now Airbus Helicopters) to produce Super Puma helicopter tails, and with Construcciones Aeronáuticas SA (CASA) aka Airbus Military (now Airbus Defense and Space) to develop the CN-235. The medium-range twin-engine transport aircraft attracted a bulk of orders from countries around the world.

But DI had bigger dreams.

Its small yet efficient size makes the N-219 useful not only as a passenger aircraft, but also for military and cargo transportation, medical evacuation, as well as surveillance and maritime patrolling.

Since 2014, the development has received official funding from the state budget. Initially scheduled to carry out its first flight this month, DI delayed the date due to technicalities with the certification process.

The maiden flight is now planned for November, when DI plans to fly two N-219 aircraft, piloted by four senior pilots: Esther Gayatri Saleh, QA Supriyadi, Adibudi Atmoko and Novirsta M. Rusli.

During the rollout in December 2015, President Joko “Jokowi” Widodo reaffirmed his administration’s full support for the propeller plane’s development in a speech delivered by then-Coordinating Political, Legal and Security Affairs Minister Luhut Binsar Pandjaitan, who represented Jokowi at the ceremony.

“The President would like to see the nation hold competitive value as the ASEAN economic community develops,” Luhut said.

Connecting the archipelago

A few years after the declaration of Independence in 1945, the nascent nation of Indonesia envisioned connecting the vast archipelago using airplanes and ships. First president Sukarno in 1950 sent a batch of young Indonesians abroad to study aerospace and maritime technology. Among the fourth batch in 1954 was Habibie, a brilliant young man who later followed in the steps of his predecessor in aerospace technology: Nurtanio Pringgoadisuryo.

In 1976, Indonesia established IPTN, at the time the “N” stood for Nurtanio, not Nusantara. Habibie was the first president director of IPTN. He was sent abroad along with the young people who were expected to connect the archipelago using either airplanes or ships. Thus, Habibie’s N-250 was designed for connecting the 17,000 islands of the archipelago.

That vision continued with the N-219.

“Our main target is to produce the most suitable aircraft for Indonesia’s remote regions,” said DI’s director of technology and development, Andi Alihsjahbana.

“What makes the N-219 different is its design, which we have specifically developed to fulfill the country’s needs. It is to be used particularly for transportation in remote regions and small islands. Indonesia needs a great number of this kind of aircraft,” said Andi, who studied mechanical engineering at ITB, Purdue University and Pennsylvania State University.

“It is not that easy. We haven’t developed any new aircraft since the N-250, and we have to start a new one from scratch. It needs some time to rejuvenate, to start thinking and be innovative,” Andi laughed a bit as he spoke.

Some local companies have been ordered to build components that were usually imported, such as landing gears, rubber components and tooling. DI strives to keep the local content for the N-219 aircraft above 60 percent. Other important components, such as the engine and the avionic system, are still imported from Canada and the US, respectively.

Said to have a bigger cabin yet come at a lower price (US$5 million) than its competitor, the $8 million Twin Otter, the N-219 has captured the eyes of many.

DI received nearly 200 letters of intent from a number of local administrations, such as Aceh and Papua, as well as local airlines, including Lion Air, Kartika Air and Nusantara Buana Air. In the international market, some African and Southeast Asian countries are considering to purchase the aircraft.

“We are very confident that our airplane can compete internationally,” Andi said.

Dreams of the future

While the future of Indonesia’s aerospace industry looks promising given the N-219’s market potential, former Indonesian Air Force chief of staff Chappy Hakim said the company’s production track record had yet to show a robust performance.

DI’s backbone has been the CN-235, the medium-range twin-engine transport aircraft produced in a joint venture between DI and CASA, now Airbus Defense and Space, a division of European company Airbus Group. Chappy said that even with its trademark work for the CN-235, DI had yet to show consistency in its production capacity.

The CN-235’s inconsistent production, he said, was the main reason why the company’s growth remained slow.

However, the aviation expert remained optimistic. If DI focused on further developing the N-219, it could easily enter international markets, Southeast Asia in particular, since air transportation facilities in the region often could not accommodate bigger aircraft.

As part of the requirements for obtaining certification from the Directorate General of Civil Aviation (DGCA) at the Transportation Ministry, the N-219 is scheduled to take a wing structure test on Aug. 10, where the aircraft must prove its ability to carry up to 3.3 tons of passengers and cargo, 500 kilograms more than its competitor, the Canadian STOL Twin-Otter, can hold.

The company aims for the N-219 to obtain the DGCA’s airworthiness certificate to enter flight operations in August 2017. It would enter commercial production in early 2017. The company is expected to produce six aircraft in the first year. Once orders reach 40 units, it aims to increase its manufacturing capacity to 12 units per year. Delivery to the first customers is targeted for 2018.

“If we can produce the N-219 in great numbers, I believe it can strongly propel the aviation industry, air transportation infrastructure as well as economic growth,” Chappy said.

“I am optimistic, always,” Chappy said, smiling. “Indonesia has the potential to lead in the global market, if we do it right.”

That dream echoes through generations, and many believe it is time to turn it into reality – including Afrizal, the 30 year-old task leader for propulsion system analysis in the N-219 project. The bachelor of aerospace engineering from ITB said his vision of constructing an airplane lived on as he took part in the development of the aircraft.

Like the moon orbiting the earth, the N-219’s design also revolved around the conditions of Indonesia, Afrizal said.

“I am sure that the N-219 has the right features to build air bridges in Indonesia,” Afrizal said with a palpable sense of hope in his voice.

-----

Originally published in The Jakarta Post tittled " N-219: Propelling Indonesia’s

aerospace industry"

| Managing Editor, News | : | Dandy Koswaraputra |

| Editor | : | Evi Mariani |

| Reporter/Writer | : | Marguerite Afra Sapiie |

| Technology | : | Muhamad Zarkasih, Muhammad Kurnia, Mustopa |

| Multimedia | : | Bayu Widhiatmoko, I.G. Dharma J.S., Ahmad Zamzami, Rian Irawan |

| Photographer | : | Wienda Parwitasari |